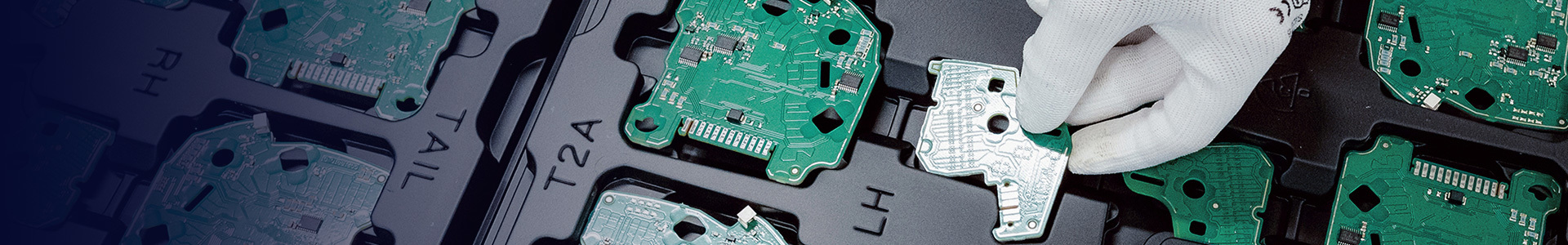

DFM

Why DFM Analysis Is Necessary

As a key link between design and manufacturing, DFM permeates the entire product design cycle to ensure efficient and cost-effective manufacturing.

Timely market entry: shortening the design cycle.

Quality improvement: reducing product defects.

Rapid mass production:Achieving mass production rapidly.

At Aurightec, DFM plays a distinct role at every stage leading up to mass production

We adapt analysis focus on the various stages of the customer's product design and provide corresponding optimization plans.

DFM

Balance design and manufacturing based on design, cost and quality requirements

Design

DFM

Check design-process match, and identify possible defects and challenges to simplify assembly.

Quotation

DFM

Perform problem tracking and DFM risk assessments based on actual yield rates.

Prototype Design

DFM

Adjust DFM guidelines to actual production for design-process match analysis.

Pilot Production

BOM Match Analysis

DFM issue

Mismatch between component package and pad designs.

Before

Failed component assembly.

After

Successful assembly and soldering by updating the MPN information of components in BOM.

Component Analysis

DFM issue

Small spacing between the pads of SMD-type devices.

Before

Short circuit due to tin connection between the pads.

After

Optimized pad design to reduce the pad width.

Pad Analysis

DFM issue

Micro short circuit due to the small spacing between the pads and traces and exposed traces.

Before

Micro short circuit due to the molten solder paste and exposed traces.

After

Optimized trace design of the BGA pad positions for highly reliable soldering.

Component Pin-Pad Match Analysis

DFM issue

Fragile components were close to the edge of the board.

Before

MLCC close to the edge of the board was damaged during routing.

After

Optimized component position design for successful routing and testing.